About Shuntec

Hydraulic Press & Machinery

We are your reliable global business partner invested in your success. From robust and durable hydraulic presses made in China to electric servo presses, servo-hydraulic presses, as well as pneumatic and air hydraulic presses, we design and build solutions tailored to your unique application.

Why Choose Shuntec

With years of engineering and manufacturing experience in hydraulic press China solutions, Shuntec has supported dozens of industries and applications worldwide. As a trusted hydraulic press manufacturer in China, we are confident in building every press to your exact specifications and exceeding your expectations.

- Facility

- Engineering

- Project Management

- Mechanical Design

- Hydraulic Design

- Electrical Design

- Parts & Components

- 7500 sq meter manufacturing factory

- Over 150 full time employees

- Over 30 tons lifting capacity

- Machine equipment for CNC machining, turning, milling, drilling, boring

- Talented technicians from a diverse mechanical background, including machine design, project management, and automation experience

- Engineering and manufacturing experience across dozens of industries and applications

- Shuntec press design begins with good project management, mechanical, hydraulic and electrical design

- Tech service team 24 hours on line for before and after projects service

- Online commissioning, training and video technical support

- Fast-response aftersales service

- Every project has a project engineer working directly with customers from design throughout delivery

- Reviewing the project application and determining deliverables proposals during an Engineering Kickoff Meeting.

- Collaborating with our customers during the design process via online or in-person design reviews.

- Improving the understanding of the unique application of our customers.

- Compliance with a variety of customer-specific machine standards, such as CE, UL.

- Managing process qualifications, runoffs on our floor (FAT), and delivery.

- Application experience to select the correct press frame based on loading conditions, tool clearance and other factors.

- Complex 3-D CAD modeling via SolidWorks Professional to ensure a robust press frame.

- Indexers, shuttles, robots and pick and place units used with press machine

- Heated and chilled platens and process chillers

- Simulation of complicated machine installs and rigging

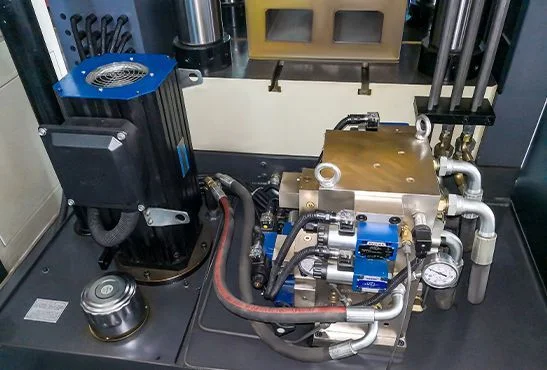

- Scalable designs as simple as discrete valving up to precision servo hydraulics.

- Clean design using proprietary integrated manifold blocks.

- Energy efficient hydraulic units through load holding check circuits, accumulators, and variable speed pump drives.

- Special attention to fluid velocity, tank size, tank layout, pump suction condition, and fluid aeration

- Fluid condition management including filtration, cooling, and sealed systems

- Redundant valving for safety compliance

- High safety factors on pressure-rated components

- Electrical design compliant with CE, UL, NFPA.

- Safety code Compliance ANSI, CSA and EN as well as pertinent OSHA standards.

- Expertise with widely accepted and modern software such as:

- PLC Programming – Allen Bradley (Rockwell Toolkit), Siemens (TIA Portal), etc.

- Delta RMC Tools

- Schematic design and panel layout using AutoCAD Electrical

- Safety controls as simple as a safety relay to full safety PLC solutions.

- Shuntec shares a long-term business cooperation directly with world-famous suppliers like Bosch, Rexroth, YUKEN, Omron, Siemens, Schneider, Allen-Bradley, Baldor, SKF.

- Our machines feature the finest hydraulic and electrical components, safe, reliable, robust and easy to maintain and support

- Extensive inventory and quick shipments on spare parts and components

Our Partners

SHUNTEC's hydraulic presses are highly popular among manufacturing companies worldwide.

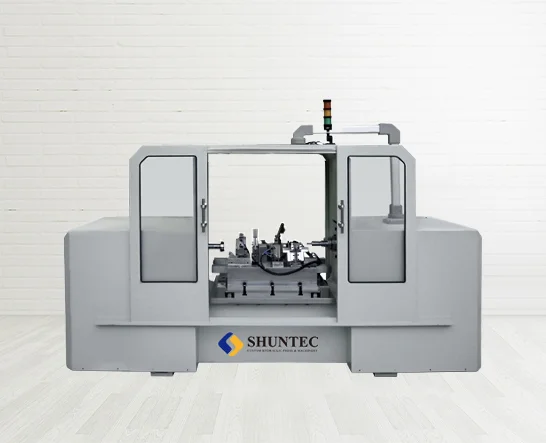

Products

SHUNTEC’s hydraulic presses from China combine superior quality and safety with advanced automation and efficiency. As a trusted hydraulic press China supplier, we empower you to handle any challenge with confidence and elevate your overall production experience.

Hydraulic H Frame Press Machine

SHUNTEC offers high-quality H-Frame Hydraulic Presses for sale with 100T to 1000T capacity. Get competitive pricing, custom specifications (stroke, bed size), and wholesale quotes from a leading China manufacturer. Ideal for automotive, aerospace, and metalworking industries.

Horizontal Hydraulic Press Machine

China Horizontal Hydraulic Press Factory Direct — Wholesale Quotes & OEM Manufacturing! Real-time Price List for Metal Forming & Pipe Extrusion. Contact Now for Exclusive Factory Deals!

Gib Guided Hydraulic Press Machine

Gib-guided press, with its sturdy construction and high accuracy, is often used for most demanding applications which the two-post hydraulic press and four-post hydraulic press are not capable of.

2-Post Hydraulic Press Machine

Shuntec’s 2-post press also called 2-column hydraulic presses, are featured by the 2-post tie-rod structure, as well as the bed table with a wider left-right yet narrower front-back working area.

Pneumatic Press Machine

China-based pneumatic press manufacturer specializes in small industrial machines (1/2 ton) and customizable heat press systems. Upgrade standard presses with heating modules (50-300°C). OEM solutions & factory-direct pricing. Request your quote now!

Air Hydraulic Press Machine

Discover high-quality 20-ton air hydraulic presses from a leading China factory. As a trusted manufacturer and supplier, we offer custom air-over-hydraulic press solutions for industrial applications. Reliable, efficient, and built to last.

Heated Platen Hydraulic Press Machine

As a leading China factory and supplier, we specialize in custom heated platen hydraulic presses for industrial applications. Explore high-quality hydraulic hot press machines for sale, designed for precision lamination, molding, and more. Durable, efficient, and tailored to your needs.

Electric Servo Press Machine

As a trusted China factory and supplier, we specialize in custom small electric servo presses (1 ton, 3 ton, 5 ton). Explore high-quality electric press machines for sale, designed for precision assembly, molding, and industrial applications. Reliable, energy-efficient, and tailored to your needs.

Benchtop Hydraulic Press Machine

As a leading China factory and supplier, we specialize in custom benchtop presses and table top hydraulic presses for industrial, laboratory, and workshop applications. Explore high-quality presses for sale, offering precision, durability, and flexible configurations. Reliable solutions tailored to your needs.

C Frame Hydraulic Press Machine

As a leading China factory and supplier, we specialize in high-quality C Frame Hydraulic Presses and C Type Press Machines. Explore custom benchtop and industrial C Frame Press solutions for metal forming, automotive parts, and precision stamping. Reliable, durable, and available for sale with flexible configurations.

Servo Hydraulic Press Machine

As a leading China factory and supplier, we specialize in custom servo hydraulic press machines for precision metal forming, automotive, and industrial applications. Explore high-performance servo press machines for sale, offering energy efficiency, durability, and advanced control systems. Tailored solutions to meet your production needs.

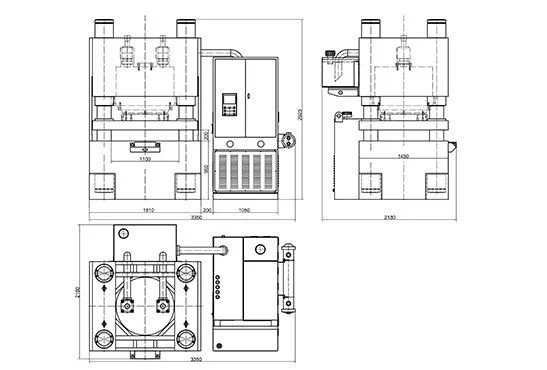

4 Post Hydraulic Press Machine

As a leading China factory and supplier, we provide high-quality 4-post hydraulic presses (four-column presses) for sale. Specializing in custom four-post presses for automotive, metal forming, and industrial applications. Durable, precision-engineered, and cost-effective solutions tailored to your production needs.

Applications

At Shuntec, the idea of ''build to your specification'' has been rooted in everyone’s mind deeply. We build the hydraulic press machines directly to meet your application.

Stamping Press

Stamping Press

Shuntec Stamping press, also widely known as general forming press, is the most universal machine equipment in the metalworking industry. It's widely used in a variety of manufacturing processes, such as embossing,

Learn MoreDie Cutting Press

Die Cutting Press

Shuntec die cutting press machines are the hydraulic press that use the cutting dies to cut

Learn MoreCompression Molding Press

Compression Molding Press

Shuntec's compression molding press machines are highly customized and built for molding SMC, BMC,

Learn MoreAssembly Press

Assembly Press

Shuntec offers standard benchtop hydraulic assembly presses and servo-electric assembly presses ranging from 0.2-50

Learn MoreAir Forming Press

Air Forming Press

Shuntec’s pressurized air bulge forming presses are ideal for manufacturing parts from a variety

Learn MoreTrim Press

Trim Press

Shuntec trim press is an extremely quick and easy-operate hydraulic press machine to remove excess.

Learn MoreDeep Drawing Press

Deep Drawing Press

From maintaining consistent heat throughout a specified dwell period to precision pressure ramping,

Learn MoreAPPLICATION

At Shuntec, the idea of ''build to your specification'' has been rooted in everyone’s mind deeply. We build the hydraulic press machines directly to meet your application.

Shuntec Stamping press, also widely known as general forming press, is the most universal machine equipment in the metalworking industry. It’s widely used in a variety of manufacturing processes, such as embossing,

Shuntec die cutting press machines are the hydraulic press that use the cutting dies to cut

Shuntec die cutting press machines are the hydraulic press that use the cutting dies to cut

Shuntec offers standard benchtop hydraulic assembly presses and servo-electric assembly presses ranging from 0.2-50

Shuntec’s pressurized air bulge forming presses are ideal for manufacturing parts from a variety

Shuntec trim press is an extremely quick and easy-operate hydraulic press machine to remove excess.

From maintaining consistent heat throughout a specified dwell period to precision pressure ramping,

Latest Informations

The Latest Informations For Hydraulics Press, Engineering, And Our Projects

Servo Press Control System Explained: Motion Control, Programmable Stroke & Precision Forming

Learn how a servo press control system works, including servo motion control, programmable stroke profiles, encoder feedback, and precision forming in modern manufacturing.

How Does a Servo Press Work? Servo Press Working Principle Explained

Learn the working principle of a servo press and how servo motor motion control improves forming precision. A practical guide for engineers and manufacturing buyers.

What Size Hydraulic Press Do I Need?A Practical Hydraulic Press Sizing Guide

Learn how to determine the right hydraulic press size based on operation type, material behavior, tooling contact area, and duty cycle.

100 Ton Hydraulic Press — Power, Precision & Versatility for Metal Forming

Explore 100 ton hydraulic presses built for precision, power, and efficiency. Ideal for metal forming, stamping, and assembly. Get factory-direct pricing from Shuntec.