Introduction

Across electronics, minting, automotive, and aerospace, manufacturers are pushing for tighter tolerances, higher repeatability, and lower waste. To meet these demands, more plants are adopting the coining press — a precision hydraulic press designed to apply extremely high, uniform pressure over a short, controlled stroke, shaping parts with minimal material flow and micro-level accuracy.

Why coining now?

- Pressure for zero-defect quality in miniature and safety-critical parts

- Need to stabilize dimensions as designs become lighter and more complex

- Drive to cut scrap and tooling costs while improving throughput

Industry insight: Adoption of precision forming equipment continues to trend upward, driven by quality, cost, and sustainability pressures rather than marketing hype.

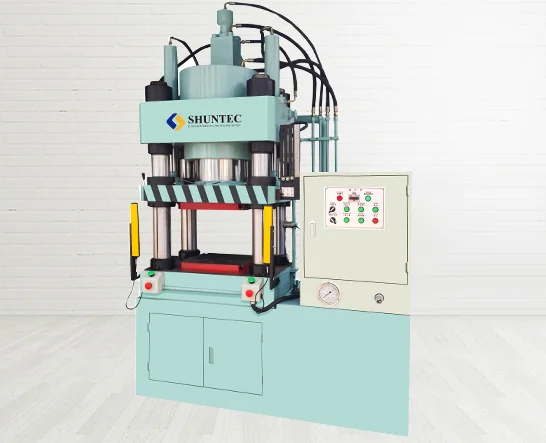

A coining press differs from general-purpose presses by prioritizing rigidity, alignment, and fine control from the ground up. While multiple suppliers contribute to this space, some — including Shuntec — have responded with customizable platforms and advanced control packages that align with these industry shifts without turning the discussion into a sales pitch.

Working Principle & Core Technologies

A coining press operates on a refined principle: applying extremely high, evenly distributed pressure over a short stroke to achieve precise shaping of metal parts. The aim is to minimize material flow while meeting tight dimensional tolerances.

How It Works

- Workpiece Placement: The metal blank is positioned between two accurately aligned dies.

- Controlled High-Tonnage Application: Hydraulic systems apply force evenly, reducing distortion.

- Pressure Hold & Release: The press maintains pressure for a set duration so the material fully conforms to the die surface.

- Part Ejection: A hydraulic cushion or ejector system removes the finished part without damage.

Core Technologies in Modern Coining Presses

- Precision Ram (or Slide) Guidance: Multi-point guidance (4- or 8-point) maintains alignment, minimizing off-center loading and extending die life.

- Bed-to-Platen Parallelism: Rigid frames keep working surfaces parallel under full load, which is critical for consistent quality.

- Adjustable Gibs: Allow fine-tuning over the press’s service life, preserving precision.

- Multifunction Hydraulic Cushion: Configurable for ejecting, non-ejecting, or blank-holding operations depending on the part design.

How It Differs from Standard Hydraulic Presses

Typical ranges; actual performance varies with rigidity, die condition, materials, and process control.

| Feature | Standard Hydraulic Press | Coining Press |

|---|---|---|

| Stroke Length | Longer, variable | Short, precise |

| Pressure Distribution | Less uniform | Highly uniform |

| Tolerance Capability | ±0.05 mm typical | Up to ±0.01 mm in optimized setups |

| Tooling Wear | Higher | Reduced due to stable alignment |

While these features can be found from different suppliers, some — such as Shuntec — integrate them into modular platforms covering capacities from 100 to 1000 tons and bed sizes up to 920×920 mm. This flexibility helps manufacturers tailor a press to both small-scale precision work and larger structural components without over-specifying or under-sizing equipment.

Applications & Industry Examples

Coining presses are indispensable in sectors where dimensional precision, surface finish, and repeatability directly impact product performance and cost. Their adaptability makes them suitable for both high-volume mass production and specialized low-batch manufacturing.

Key Application Areas

- Minting & Currency Production

- Produces coins with exact thickness, diameter, and intricate surface details.

- Uniform pressure ensures consistent engravings and minimal dimensional variance.

- Precision Electronics

- Forms semiconductor housings, electrical connectors, and EMI/RFI shielding parts.

- Maintains extremely tight tolerances to support automated assembly lines.

- Aerospace Components

- Shapes small brackets, fastener heads, and control system components.

- Balances high strength-to-weight ratio with flawless surface finish.

- Medical Devices

- Produces surgical instrument tips and implantable device housings.

- Delivers burr-free edges and clean surfaces for patient safety.

Illustrative Case Insights

Example 1:

A precision electronics manufacturer reported a ~25% scrap reduction after adopting a coining press with enhanced ram guidance and programmable pressure control. The consistency in output reduced downstream rework and improved delivery timelines.

Example 2:

In a minting scenario, the uniform pressure profile of a coining press was associated with die life extensions of up to ~40%, lowering annual tooling costs.

From General Capability to Tailored Solutions

While these examples highlight what a coining press can do, many manufacturers now prefer custom-configured systems.

Suppliers — including Shuntec — offer modular designs where users can choose:

- Tonnage range (100–1000 tons)

- Bed size (up to 920×920 mm)

- Optional automation such as feeding/collecting systems, quick die change, and integrated PLC control

This approach ensures that each press matches specific product requirements, avoiding wasted capacity while leaving room for future upgrades.

Technical Advantages & Economic Benefits

A well-specified coining press delivers value on two fronts: technical capability and financial return. By combining high precision with consistent performance, it supports both quality targets and cost-efficiency goals.

Technical Advantages

- High Rigidity Frame

- Minimizes deflection under full load, ensuring uniform pressure across the die surface.

- Improves part consistency and reduces dimensional deviation.

- Multi-Point Ram (or Slide) Guidance

- Four- or eight-point guidance maintains alignment, reducing off-center loading.

- Extends die life and lowers tooling maintenance frequency.

- Bed-to-Platen Parallelism

- Maintains accurate die contact even at maximum tonnage.

- Essential for parts with intricate geometries or fine surface details.

- Modular Design for Customization

- Adaptable structure and hydraulic system for specific applications.

- Supports future integration with automation and upgraded control packages.

Economic Benefits

- Reduced Scrap Rates

- Consistent process control leads to fewer rejected parts and lower material waste.

- Lower Tooling Costs

- Stable alignment extends die life, reducing replacement frequency.

- Higher Production Efficiency

- Programmable controls allow quick changeovers between jobs, reducing downtime.

- Better Return on Investment (ROI)

- In favorable conditions, modeled payback can be achieved within roughly 12–18 months; results depend on part geometry, production volume, scrap rates, and tooling costs.

Example — Matching Specs to Needs

In a pilot run at a mid-sized facility producing precision metal housings, a 500-ton coining press with a 750×750 mm bed delivered:

- ~15% faster cycle times due to optimized stroke control

- ~30% fewer tool changes over 12 months

- Improved surface finish, reducing secondary finishing steps

Where Shuntec Fits In

While several manufacturers offer similar technical capabilities, suppliers like Shuntec combine:

- Tonnage range from 100 to 1000 tons

- Bed sizes up to 920×920 mm

- Optional automation (feeding/collecting systems, quick die change, programmable PLC controls)

This flexibility enables customers to specify exactly what they need, ensuring cost-effectiveness without sacrificing capability.

Selection & Purchasing Guidelines

Selecting the right coining press is about finding the best fit between your production requirements and the machine’s capabilities. Over- or under-specifying can lead to wasted investment, higher operating costs, or compromised product quality.

Key Factors to Consider

- Tonnage Capacity

- Choose based on material properties, part size, and target tolerances.

- Avoid oversizing (higher purchase and operating costs) and undersizing (risk of inadequate forming).

- Stroke & Daylight

- Stroke length: determines ram travel distance.

- Daylight (maximum open height): impacts the size of dies and parts you can handle.

- Bed Size & Rigidity

- Larger beds accommodate bigger dies or multi-cavity tooling.

- Rigid structures ensure accuracy under load.

- Control Systems

- Programmable settings, touchscreen HMIs, and integration with automation improve flexibility and productivity.

- Safety & Maintenance

- Look for features such as light curtains, two-hand controls, and overload protection.

- Easy access for maintenance and adjustable gibs reduce downtime.

Example Parameter Ranges

Typical ranges; actual selection should be based on application-specific requirements.

| Tonnage Range | Max. Bed Size (mm) | Typical Applications |

|---|---|---|

| 100–300 T | 500×500 to 650×650 | Small electronics, medical parts |

| 400–700 T | 750×750 to 850×850 | Medium-size aerospace components |

| 800–1000 T | up to 920×920 | Large structural parts, minting |

Note: Modular product lines from suppliers like Shuntec cover all of these ranges, enabling capacity, bed size, and automation features to be tailored to the specific product mix.

Practical Buying Tips

- Assess Long-Term Needs: Plan for potential product changes, volume increases, or new materials in the next 5–10 years.

- Request a Trial or Demo: Testing with your actual tooling and materials helps confirm fit.

- Evaluate After-Sales Support: Reliable service and spare parts availability are critical to uptime.

Industry Trends & Future Outlook

The role of coining presses is expanding as manufacturing moves toward automation, smart data integration, and material innovation. Staying ahead of these trends ensures that equipment investments remain relevant and competitive over time.

Automation & Integrated Production Lines

- Robotic Material Handling

Automatic feeding and collecting systems reduce manual labor, improve cycle consistency, and lower handling errors. - Quick Die Change Systems

Minimize downtime during product changeovers, supporting shorter runs and just-in-time manufacturing. - End-to-End Process Control

Seamless integration with upstream and downstream operations enables continuous, automated workflows.

Smart Controls & Industry 4.0

- Programmable Logic Controllers (PLC) with touchscreen HMIs allow storage of multiple job recipes, on-the-fly adjustments, and performance monitoring.

- Data Logging & Analytics

Records pressure curves, cycle times, and maintenance events for process optimization and predictive servicing. - Remote Monitoring

Supports off-site troubleshooting and parameter changes to minimize downtime.

Materials & Application Expansion

- Lightweight Alloys in aerospace and automotive demand precise forming to maintain strength and integrity.

- Medical-Grade Stainless Steel & Titanium require burr-free finishes and strict dimensional control.

- Specialty Copper Alloys for electronics benefit from uniform micro-forming to ensure conductivity and fit.

Implications for Buyers

Coining presses are shifting from stand-alone machines to connected, flexible, and application-specific systems. Equipment with modular automation options, advanced control packages, and scalable bed sizes helps manufacturers adapt to future demands without costly replacements.

Example of Market Alignment

Some suppliers — including Shuntec — already offer features such as automated feeding/collecting devices, fully programmable control systems, and modular hydraulic cushions, allowing customers to align with Industry 4.0 strategies from the outset.

Conclusion & Next Steps

Coining presses have become a cornerstone technology in industries where precision, repeatability, and efficiency are non-negotiable. By delivering high, uniform pressure with exceptional accuracy, they enable manufacturers to:

- Achieve consistently high part quality

- Reduce scrap and tooling costs

- Shorten production cycles

- Handle complex geometries and challenging materials

Why an Informed Decision Matters

Investing in the right coining press is about matching capability to production needs, both now and in the future. Factors like tonnage, bed size, automation readiness, and control sophistication should be weighed alongside lifecycle cost and return on investment.

A Practical Path Forward

For decision-makers evaluating new equipment, a good next step is to:

- Identify current production challenges and constraints

- Define the range of parts, materials, and tolerances you need to support

- Compare specifications, service offerings, and upgrade paths from multiple suppliers

- Where possible, run sample production tests using your own tooling and materials

Industry note: Manufacturers such as Shuntec can provide detailed technical specifications, application case studies, and configuration options to help align your investment with operational goals — whether that’s scaling production, improving precision, or integrating into an Industry 4.0 workflow.

Final Thought

A coining press is more than a machine — it’s a long-term production partner. The better it matches your specific needs, the greater the benefits in quality, productivity, and profitability over its service life.